SATE-EDI-WEST - AUTONOMOUS INTEGRATED DIAGNOSTICS FOR PREDICTIVE ONBOARD FAULT DETECTION

OVERVIEW AND APPLICATIONS

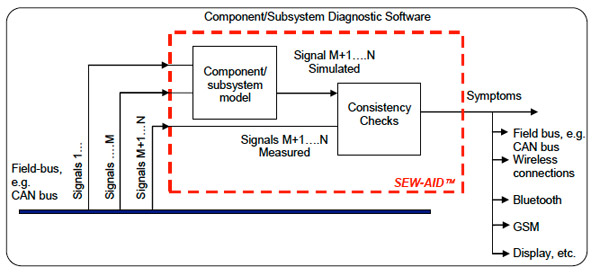

SEW-AID is a stand-alone system, developed and manufactured by the SATE / EDI-WEST consortium, providing advanced, model based, diagnostic functionalities. It can be configured with connectors and protocols which allow connections to various field-bus technologies or direct access to transducers and has large memory and computing capability to meet the needs of many industrial applications.

SEW-AID includes several diagnostic algorithms (based on either “black box” models, e.g. Neural Networks, State Space, etc. or specific “transparent box” models, i.e. based on physical-mathematical equations).

OPERATIONAL SCENARIOS

The SEW-AID with the CAN interface has been originally designed for the automotive field. This has allowed designing and implementing models able to detect incipient faults of components and subsystems, such as:

- Lube oil systems

- Cooling systems

- Powertrain systems

- Engines / power machines

The large experience gained by Attain IT and the SATE / EDI-WEST consortium in the diagnostic field makes the SEW-AID suitable for all the applications that make use of the CAN interface.

In fact Controller Area Network (CAN) serial bus system is not only limited to the automotive application but is ever been used to a broad range of embedded as well as automation control systems.

The main CAN application fields span:

- Automobiles

- Trucks and buses

- Off-highway and off-road vehicles

- Tractors

- Passenger and cargo trains

- Maritime electronics

- Aircraft and aerospace electronics

- Factory automation

- Industrial machine control

- Lifts and escalators

- Building automation

- Medical equipment and devices

SEW-AID is the viable answer to all the cases where predicting the evolution of incipient faults is fundamental either to avoid costly systems shut-down and reduced availability or to allow a cost-effective Global / multiyear guarantee and support service by OEMs.

OPERATIONAL MODES

SEW-AID can be supplied for two different operational modes:

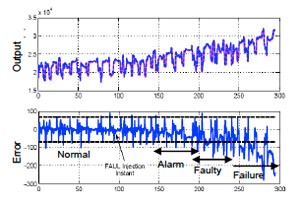

- Diagnostic Mode (DM), for online operational diagnostics: pre-defined signals are acquired and used in the models to produce “symptoms” from which the status of the system or component can be derived, either “normal”, with “incipient anomalies” or “faulty”.

- Acquisition Mode (AM), for prototype development of diagnostic systems: signals are just acquired to monitor performances and allow the subsequent definition of a diagnostic strategy, identify the needed models and setup the diagnostic functions.

The base version of the SEW-AID has robust factory built-in definition of the signals sets to be acquired using the AM. Upgraded versions can have features to enable the user to customize the data set through a runtime setup software by user-friendly options access.

The algorithms parameters for the DM are provided by Attain IT to the end-user in two possible ways:

- Data-acquisition and model identification service: the Customer installs the SEW-AID on its prototype product (e.g. car) and returns it after drive test completion with no other burden than connecting/disconnecting and shipping the box; Attain IT analyzes the signals and return the SEW-AID configured for diagnostic functionalities procured.

- Model identification service: the customer acquires the signals needed or candidate for the diagnostic functionalities on its own and delivers to Attain IT files of standardised format with the signals; Attain IT analyze them and return the SEW-AID reconfigured for the diagnostic functionalities procured.

In both cases the delivery consists in the supply or update of the SEW-AID firmware, suited for the specific on-board diagnostic application, whose installation can be performed following customer’s general procedures for ECU software updates.

SOFTWARE INTERFACE: SEW-AID MANAGER

The SEW-AID Manager is a complementary support software allowing the user to easily manage the most frequently actions, such as: operational mode change, data download, data reset.

MICROCONTROLLER

Type

Automotive Microcontroller Renesas M30853FHFP 32 bit, 32 MHz

Internal Memory

ROM: 388 kB / RAM: 24 kB

Other Characteristics:

Timer

2 Timer (16 bit) with 5 and 6 channels respectively

Serial Interface

Clock synchronous serial I/O, Clock asynchronous serial I/O, IEBus1, I2C bus2.

A/D Converter

10-bit A/D converter: 1 circuit, 10 channels.

D/A Converter

8 bits x 2 channels.

CAN Module

2 channels Supporting CAN 2.0B specification.

CRC Calc. Circuit

CRC-CCITT.

Watchdog Timer

15 bits x 1 channel.

Clock Gen. Circuit

Main clock oscillation circuit(*), Sub clock oscillation circuit(*), On-chip oscillator, PLL frequency synthesizer.

Oscil. Stop Detect

Main clock oscillation stop detect function.

Voltage Detect. Circuit

Available.

ADDITIONAL MEMORY

RAM

1 MB

FLASH

32 MB (expandable to 64 MB)

INTERFACE

CAN Module

1 (expandable to 2) CAN 2.0B channel (up to 1Mb/s).

Serial Interface

2 LIN channel for communication with SEW-AID Manager and an optional peripheral (e.g. warning LED).

A/D Converter

10-bit A/D converter: 7 channels.

Digital Input

8 channels for signals 12-24 V.

ELECTRICAL CHARACTERISTICS

Supply Voltage

6-30 V

Power Consumption

ON

60mA (Vcc = 13,5V)

IDLE MODE

< 100µA (Vcc = 13,5V)

Protection

Protection against over voltage, inverse polarity, short circuit to mass or power supply of all the communication channels.

OPERATING AMBIENT

Temperature

– 40° C to +85° C.

Pressione

Ambient

Umidity

Must be avoided installation in ambient where it is possible water condensation on the SEW-AID.

Vibrazioni

5 g sine-sweep from 5 a 2000 Hz.

Shock

25g peak acceleration in three axes.

ENCLOSURE

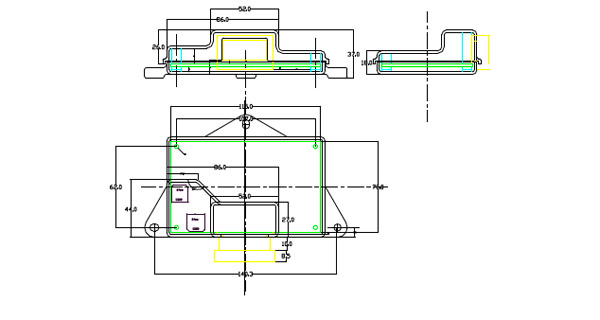

Material

Aluminum box – UNI 9006/4.

Overall mass

250 g

Size

155 x 112 x 37 mm

Connector

24 pins FCI connector for I/O signals and power supply. (Male Cod. HCCPHPE24BKA90F, Female Cod. 211PC249S0005)

1. EBus is a trademark of NEC Electronics Corporation.

2. 2C bus is a trademark of Koninklijke Philips Electronics N. V.

Version: 03/03/2006

SATE / EDI-WEST reserve to modify the technical characteristics of this product without notice.